HYPERCENTRIC LENSES

What the heck is a hypercentric lens?

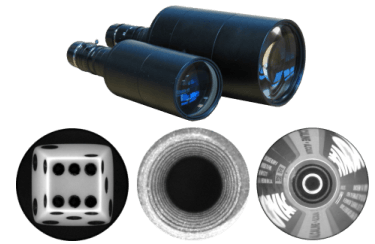

A hypercentric lens provides a converging view of an object, letting you see the top and all around the sides simultaneously. Some call it a pericentric lens. Either way it's a remarkable new tool for your machine vision inspection challenges.

Hyper-EyeTM also has another trick up its sleeve. Add a spacer ring, and now you have a long working distance borescope. Take a look at the 1/4-20 threaded hole in the above image. The extra working distance makes illumination much easier.

Whether you're inspecting caps, containers, batteries or bolts, Hyper-EyeTM lets you see everything with one camera. Achieve a unique perspective with Hyper-EyeTM hypercentric/pericentric lenses.

Here's how they work!

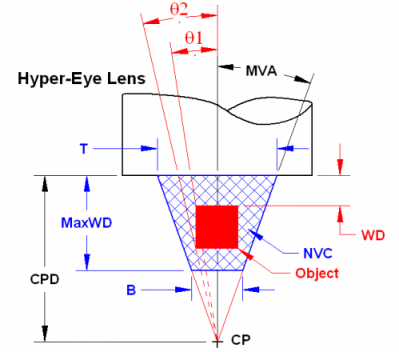

Hyper-Eye receives rays of light as if they all originate from a single Convergence Point (CP). The distance from the front of the lens to CP is cleverly called the Convergence Point Distance (CPD).

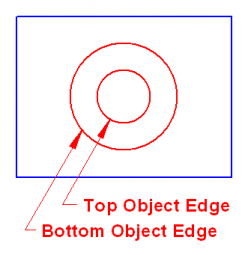

Any object that is within the Near Viewing Cone (NVC) can be focused onto the camera detector. Rays of light that are collected at smaller angles (q1) are imaged closer to the center of the detector. Those collected at higher angles (q2) are imaged farther out. A cylindrical object might be imaged like this:

The NVC is an inverted, truncated cone (shown as the blue hatched region) that has different dimensions for each different lens model. Its dimensions are T for the top diameter, B for the base diameter, and the height called the Maximum Working Distance (MaxWD). Anything outside these diameters won't be viewed. Anything farther than MaxWD can't be optimally focused. (There's an exception when Hyper-Eye is used as a long stand-off borescope, imaging areas well beyond the CP.)

Frequently Asked Questions

1. What is a hypercentric lens, and how does it work?

Hypercentric lenses have a special design. In essence, it lets the lens accept only rays of light that pass through a point in front of the lens that we call the Convergence Point (CP), or rays of light that seem to come from the CP. In optical terms, this point is also called the Entrance Pupil of the lens, and being physically outside the lens and in front of it is the unusual part.

2. How does a hypercentric lens differ from standard or telecentric lenses?

Standard or conventional lenses have a diverging field of view. If you think of a lens as working backwards, a standard lens has light spreading out from it. A telecentric lens has a field of view that stays constant. If you think of it as working backwards, the light comes out as a collimated beam. Hypercentric lenses have a converging field of view, as if looking only at a small point in front of it. Again, if you think of it as working backwards, the light converges to a point in front of the lens called, naturally enough, the Convergence Point.

3. What are the main advantages of using hypercentric lenses in imaging applications?

There are two distinct advantages of hypercentric lenses. The first and most obvious is that they can view the top and sides of an object simultaneously. For example, a hypercentric lens can look straight down on top of a bolt head, but also see 360 degrees of the sides of the bolt head. Or looking at it from the other end the hypercentric lens can view the end of the bolt as well as the threads all around. Not only does this allow a single camera to perform an inspection that might otherwise take 3, 4, or more, but it saves valuable space around constricted production lines.

The second distinct advantage of hypercentric lenses, at least of Light Works' patented Hyper-EyeTM hypercentric lenses, is that they can also be used as long-standoff borescopes or pinhole lenses. They can be configured by the user so that objects farther away from the Convergence Point (CP) can be imaged. The result is that the CP acts as a little virtual lens that may be inserted inside bores or through small holes in larger objects, while the actual physical lens remains outside.

4. In which industries or use-cases are hypercentric lenses most commonly applied?

Hypercentric lenses find a great deal of use in the fasteners industry where all sides of bolts and screws must be imaged, as well as in the pharmaceutical and packaging industries where the containers and their labels must be inspected 360 around. And when used as long-standoff borescopes or pinhole lenses, any industry where drilled or especially threaded holes must be inspected is an excellent field. The same goes for when components such as springs, c-clips, and o-rings must be inspected for proper placement inside holes.

5. What factors should be considered when selecting a hypercentric lens for a specific application?

When selecting a hypercentric lens, many of the same factors you consider for standard lenses apply. First look at the camera you want to use, in particular the mount and size of the detector. Make sure to pick a hypercentric lens that will work with your camera format. Another factor is the actualy size of the field of view (FOV) that you need to inspect. Next comes the depth of field you might need. For example, what are the range of dimensions of the object being inspected, diameter and height.

An important factor with hypercentric lenses that usually is NOT an issue with conventional lenses is that the diameter of the hypercentric lens must be considerable larger than the diameter of the object being inspected, at least when the lens is used for a converging view to see 360 around the outside of an object.

Any lens specification can sometimes be tricky, and we admit hypercentric lenses can have additional unusual challenges. Regardless, one of the things that Light Works takes great pride in is helping our customers in detail with their application needs. If you think a hypercentric lens might provide a solution, contact us to discuss your application for a completely free consultation. We promise to give you our best advice, even if it means suggesting our competitiors' products, or even non-optical solutions! We do it all the time.